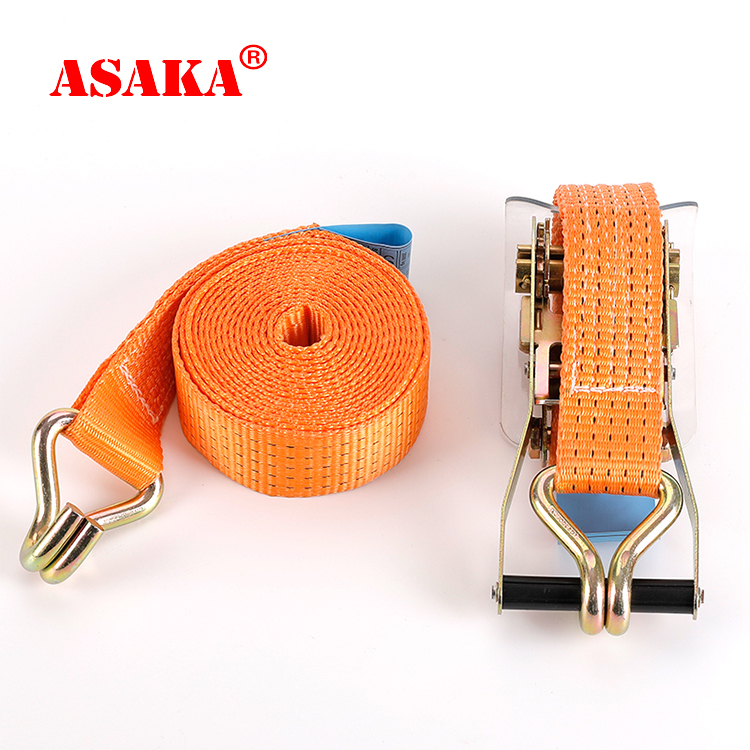

Ratchet Tie Down are used to repair functions when transporting, moving, transporting or storing goods. They have a locking function and will not fall off. They are safe, lightweight, easy to operate and protect objects from damage. It is a fixture used to reinforce steel form work and compaction wood, mainly for Ratchet Tie Down

It is a fixture used to reinforce steel form work and compaction wood, mainly for ratchet tie down. Tighten with equipment and secure with a bow. It is easy to operate and more than ten times more expensive than other fastening methods.

The Ratchet Tie Down is used to repair the function when transporting, moving, transporting or storing goods. Steel rope ratchet tie down They have a locking function and do not fall off. They are safe, lightweight, easy to operate and protect objects from damage.

The belt conveyor fixed the capstan ratchet tie down device, the automatic control system is set on it, forming the automatic ratchet tie down device, is the modern large-scale belt conveyor widely used in the ratchet tie down form. Because the automatic ratchet tie down device must complete the automatic ratchet tie down process, the structure and control of the ratchet tensioner device are very complicated.

The difference between automatic ratchet tie down device and fixed ratchet tie down device is that it has sensing element and control system. Due to the bad environment of the belt conveyor equipment for bulk materials, sensing components and control systems are greatly affected. The design and use of the practical automatic ratchet tie down device must fully consider the impact of the environment, and various automatic ratchet tie down devices have been proposed or used to solve the problem;

From the point of view of the control method, the automatic ratchet tie down device has a stable subsequent type and a combination of stable and subsequent characteristics. Stable automatic ratchet tie down device does not depend on the change of conveyor load, adhesion of nylon conveyor belt and drive roller. Other parameters, such as conditions, can be set according to starting, braking, normal operation and other conditions of the tension under different conditions, in the working state, the strap tie down device is equivalent to a fixed ratchet tie down device, therefore, only the rubber separation point of the tension can be kept constant within a certain error range

Subsequent ratchet tie down device can keep the external force at a constant value, even under the same working condition, stable driving force transmission can also through the follow up to ensure that the tension winch, namely the tension winch is a kind of automatic integration of automatic ratchet tie down device, its characteristic is when the rubber belt conveyor start its action mode for follow-up action, its action mode stable during stable operation, Before starting the belt conveyor, increase the tension required for starting, and then start the driven main motor, and the belt conveyor begins to start. After the conveyor reaches a stable operating speed, the tension of the heat-resistant conveyor belt will maintain a high value in the starting state. The tension is reduced to the tension required for stable operation. In normal operation, the ratchet tie down device is basically not operated. When the tension changes greatly, the ratchet tie down device starts to operate and automatically adjust the ratchet tie down force;

Hydraulic automatic ratchet belt tensioner device is an automatic ratchet tie down hydraulic system in a telescopic belt conveyor. The ratchet tie down device has a storage function, and the storage belt is manually operated and operated on a belt conveyor. When the hydraulic system automatically adjusts the tension of the conveyor belt, when the tension of the rubber belt is greater than the specified value, the control valve moves downward. The hydraulic control valve also moves downward due to the pressure difference created by the check valve. The hydraulic motor idles to loosen the rubber band. When the tension of the wear belt reaches the specified value, the control valve is in the middle position, and the automatic control valve is also in the middle position. Oil from the pump flows directly back to the hydraulic tank, where it expands under the spring force. In the braking state, keep the ring working normally, and meet the production rhythm.

Post time: Jul-19-2021